Our

Story

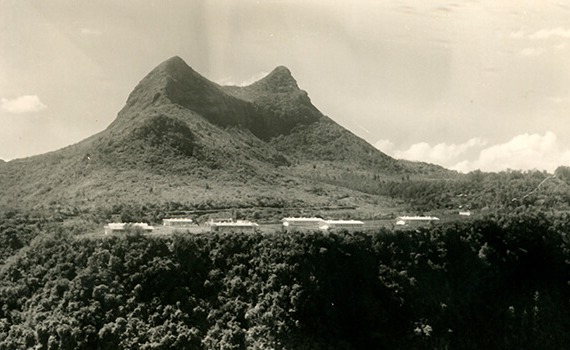

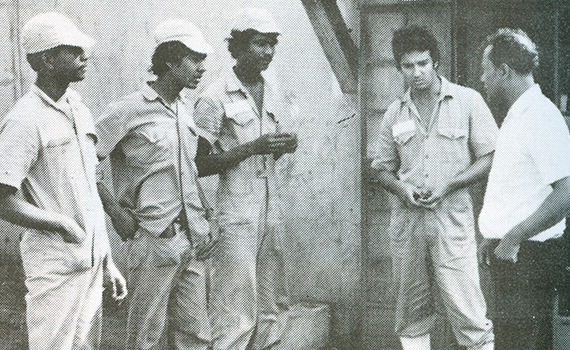

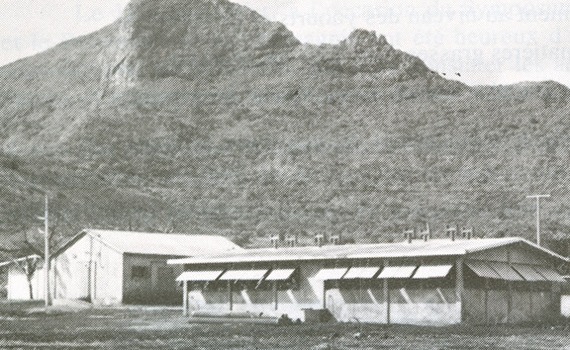

Formerly known as Food and Allied Industries Ltd, Avipro Co. Ltd is Eclosia Group’s very first company to come into being in 1966. A pioneer in poultry production in Mauritius conforming to extremely strict biosecurity standards, Avipro has always delivered on its promise of offering products that are both safe and tasty.

2020

2019

2017

2016

2011

2000

1999

1995

1985

1980

1978

1975

1973

1968

1967

1966